MANAGEMENT OF FRACTURED ABUTMENT SCREWS

Christopher R. Resnik, DMD, MDS

Post-prosthetic complications with implant prostheses occur at a rather high rate. Adler et. al., reported in a 15-year retrospective study that approximately 32% of implant prostheses exhibit technical complications. [1] One such technical complication that is frustrating to clinicians and patients is abutment screw fracture. Abutment screw fractures usually occur secondary to screw loosening, however can occur from other factors such as improper prosthesis insertion, excessive torque, or material fatigue. [2] The incidence of screw fracture in the literature varies from 0.5-8%. [3] [4] [5]

Retrieval of retained fractured screws can be quite challenging for the clinician. Irreversible damage to the implant body may occur when aggressive screw-retrieval techniques are attempted. Most commonly, low or high-speed handpieces are used to “drill” out the fractured screw which may result in irreversible damage to the internal threads or implant body. (Figure 1) Therefore, this article will describe a systematic protocol for the atraumatic removal of fractured abutment screws.

The clinician must evaluate and answer two questions when determining what technique to use for abutment screw fracture removal.

- Is the screw fractured above or below neck of the implant?

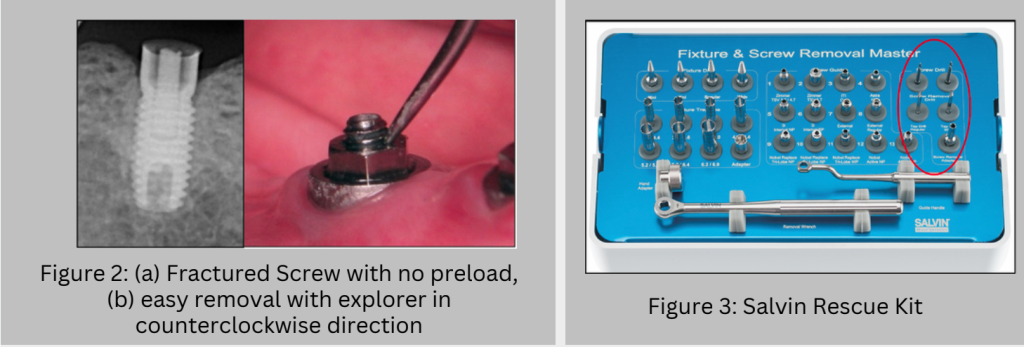

In general, screws fractured above the neck of the implant are much easier to retrieve than screws broken off inside the implant body. Access to the screw is much easier and usually an explorer, spoon excavator, hemostats, or ronguers are able to engage the screw to remove in a counterclockwise direction, even in cases with screw preload. (Figure 2)

- Does the fractured screw contain Preload or No Pre-Load?

When a screw fractures with preload (i.e., torquing or clamping force between the screw and implant threads) successful removal is much more challenging. Because the torquing or clamping force is present on the screw-implant interface, simple counterclockwise removal via methods above will most likely not be successful. Although there exists many possible methods in the literature, I have found these two atraumatic methods to work when preload exists with a high degree of success.

Ultrasonic Scaler:

An ultrasonic scaler (# 3 tip) is used by placing the scaler tip at the superior most part of the fracture screw. Using a gentle reverse torque, the vibrating or oscillations from the scaler tip may dislodge the screw via preload reduction, thereby “spinning” the screw out of the implant body. [1]

Screw-Removal Kit:

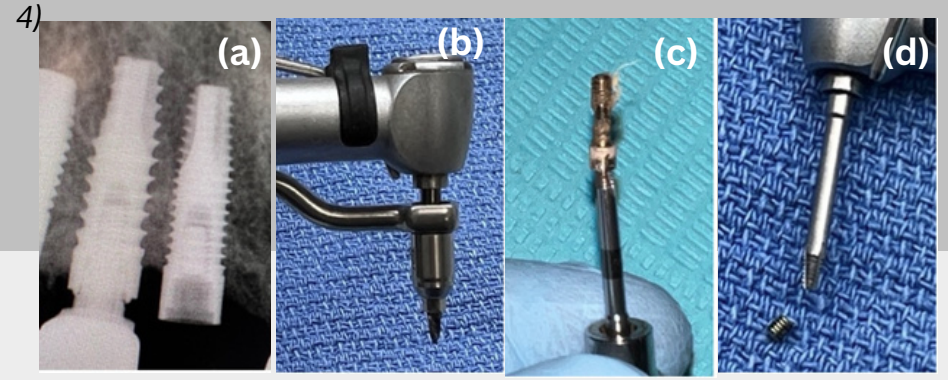

Salvin Dental manufactures a screw-retrieval kit (Rescue Kit) that is compatible with the majority of dental implant platforms. The purpose of the screw-retrieval kit is to protect the internal threading of the dental implant. After a dimple is created in the screw, a screw tap is used to back out the fractured implant screw. The following is a step-by-step protocol for removing fractured screws with preload: (Figures 3, 4, 5).

Figure 4: Case Report:

(a) fractured screw with preload,

(b) Implant screw drill and guide,

(c) after removal with screw removal TAP,

(d) fractured screw

Step 1. Identify the guide tube that is compatible with the dental implant platform. The Guide tube will be attached to the guide tube handle and inserted into the implant. This will protect the internal aspect of the implant.

Step 2. Place the implant screw drill into a latch type implant handpiece. Set motor to REVERSE at 1,000-1,250 RPM and 50-70 NCM torque.

Step 3. Drill in REVERSE using COPIOUS IRRIGATION with “up and down” motion to prepare a 1 – 2 mm deep dimple into the broken screw. External irrigation is recommended to prevent overheating.

Step 4. Insert Screw Removal TAP drill into implant handpiece. Set motor to REVERSE at 70 – 80 RPM and 50 – 70 NCM torque.

Step 5. Insert Screw Tap drill into dimple of the broken screw. With firm apical pressure, reverse the broken screw out.

Although not common, an abutment screw fracture results in an unpleasant experience for the patient and the clinician. Unfortunately, many times, removal of fractured screws may be very difficult and time-consuming, which may not be successful. Failure to remove the screw can result in significant morbidity as the implant will need to be removed, followed by bone grafting and placement of another implant. Therefore, when removing screws, it is imperative that implant clinicians have a strong understanding of abutment screw mechanics (preload vs. no preload) and various techniques of screw removal.

In summary, screws fractured above the neck of the implant with no preload are usually removed without difficulty. A screw fracture below the neck of the implant with preload, is difficult and may not be successful. The following two methods discussed will remove preload fractured screws with a high success rate and preserve the internal threads of the implant.

[1] Goodacre CJ, Kan JY, Rungcharassaeng K. Clinical complications of osseointegrated implants. J Prosthet Dent. 1999;81:537–52

[2] Nergiz I, Schmage P, Shahin R. Removal of a fractured implant abutment screw: A clinical report. J Prosthet Dent. 2004;91:513–7.

[3] Shah K, Lee DJ. An alternative approach for the management of fractured implant abutment screws on a mandibular implant-retained overdenture: A clinical report. J Prosthet Dent. 2016;115:402–5.

[4] Yilmaz B, McGlumphy E. A technique to retrieve fractured implant screws. J Prosthet Dent. 2011;105:137–8.

[5] Nayana P, Nayak SS, Chatterjee A, Sivaraman K, Srikanth G, Singh C. Retrieval of Fractured Implant Abutment Screws: A Narrative Review. J Int Soc Prev Community Dent. 2022;12(3):287-294.

[6] Gooty JR, Palakuru SK, Guntakalla VR, Nera M. Noninvasive method for retrieval of broken dental implant abutment screw. Contemp Clin Dent. 2014;5:264–7.